For many homeowners, ductwork insulation is an important step for improving energy efficiency in the home. Insulating ducts can help prevent hot and cool air from being lost as it travels through the system, reducing energy bills and increasing comfort levels indoors. But how do you go about insulating it properly so that energy is not wasted?

The blog will look at the steps needed to ensure your ductwork works efficiently and minimize energy loss. We’ll also provide tips on the best materials and methods to insulate your ductwork. Let’s get started.

Why Insulate Ductworks?

The ductwork system is responsible for circulating warm and cold air throughout your home. If your ducts aren’t insulated perfectly, the air moving in your home will be affected by external conditions responsible for circulating cool and hot air. Consequently, your HVAC system must work extra to reach a moderate temperature level.

Briefly, HVAC working extra means higher energy bills.

Moreover, the duct system that isn’t insulated accurately is prone to leakage. Leakage isn’t only responsible for HVAC system overworking and higher bills. There are some of the other results you might face. For example, you’ll see extra dust blown to your house. There may be moist and strange smells and severe allergies.

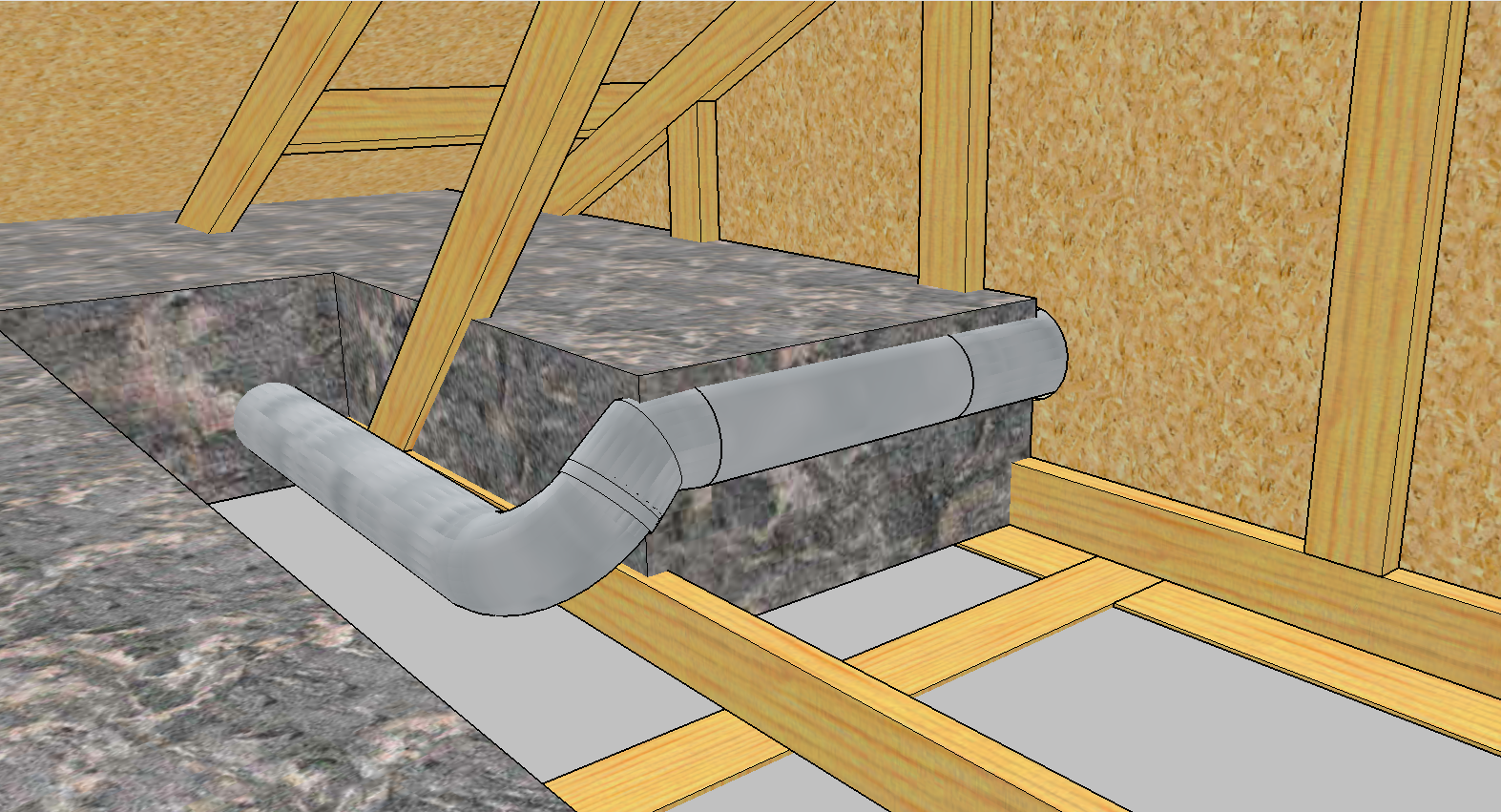

If the price is acceptable, then you should keep attic ducts neat. The money you spend on such a project will eventually be worth it by energy savings monthly. Particularly, you’ll find this real when air ducts are installed in unconditioned areas, including the attic.

Environment-Friendly

Insulating the ductwork network means you’ve reduced your overall carbon footprint and made your home more efficient.

Less Stress On The HVAC System

The air moving through the ductwork system will not lose its temperature as it moves to your house. Your HVAC system does not need extra work to reach your expected temperature. As a result, your unit will last longer. It’ll be amazing knowing that it makes your HVAC life longer if you are financially conscious.

Good Air Quality

Accurately insulated ductwork is less prone to leaks, so your system will be less likely to bring in dust or unpleasant smells from the unconditioned air outside your system.

A Peaceful Household

Insulated air ducts lead to the HVAC system running less often. While the system is running, the air movement throughout the duct is quieter, which makes your household peaceful.

Moreover, in a few parts of different countries, you can also enjoy tax breaks available for house owners who undergo insulation projects, mainly when updating old homes. However, it depends on the state you are living in.

Types Of Ductwork Insulation

Generally, there are three types of ductwork insulation used on air ducts. A few of this insulation can be used inside the actual ducts, which is perfectly practical if you use ducts for a brand-new HVAC system. You’ll use such insulation on the outer side of your ductwork network more often. Here are the three types of insulation:

1. Duct Board

A duct board is a flat study material that comes in numerous R-values. Duct boards are generally inflexible, which is why it is only typically used along with rigid ductwork. While duct board might be viable in modern homes, you might face some challenges in tight spaces due to its shape and size.

2. Duct Liner

A duct liner is used inside the actual ducts. It may only be practical to utilize once you entirely pull out your HVAC system. It is made from glass wool, a fibrous material with multiple air pockets. It’s worked into rolls of various thicknesses that come in different R-values.

3. Duct Wrap

Duct wrap insulation is generally used outside the ductwork to protect against heat transfer and other elements. It is wrapped and measured around sheet metal ducts to install. Moreover, it comes in various materials, such as simple bubble wrap, fiberglass, and others for insulating ductwork.

The R-Value

While shopping for insulation, you’ll encounter the term “R-value” various times. R-values indicate the thermal resistance every insulation has. The higher the insulation R-value, the more resistant it is to flow. Each part of the country or place requires insulation with different R-values.

Different Materials For Insulation Types

Most duct insulation is made up of three standard materials. You can decide which material is suitable for you and what you want to use considering your budget, your home, the space you’re insulating, and the types of ducts you’ve. Three types of duct insulation material are:

1. Fiberglass

The most common material of insulation is fiberglass. If you ask anybody to visualize insulation, he’ll surely imagine puffy rolls and pink color for fiberglass insulation. Flexible rolls of fiberglass are particularly well-fitted because their pliable shapes can be conveniently contorted around complex ductwork.

2. Polyethylene

Polyethylene insulation is expensive compared to fiberglass. Most experts say polyethylene is well suited for outdoor ductwork because it can withstand the elements. Also, it’s very thick and much more durable than fiberglass, which makes it a great choice for thicker insulation jobs.

3. Rock Wool

This type of insulation is also known as mineral wool or slag wool. It’s made from molten rock spun into fibers to make a material that can be used in many applications. Rock wool contains soundproofing features. While insulating the inside of your ductwork then, Rockwool is a perfect choice for you.

It is an excellent choice because of its durability, which makes it less likely to tear. If you want everything to be eco-friendly, you can select Rock wool because it is made of recycled materials, making it a green alternative. You will be able to find a variety of sizes and thicknesses for the insulation so that you can pick the best option for your needs.

Steps To Insulate Your Ductwork:

Initially, the process of insulation seems straightforward. However, it can get tricky in tight space areas where the ducts are hard to reach or at awkward angles. If you find it extremely difficult, then it’d be better to contact professionals instead of trying DIY.

Step 1: Assess The Situation First

Before insulating your ducts, it’s important to assess the situation and determine if it is necessary. Inspect your system for any air leaks or gaps that need to be filled in before insulation is applied. You should also measure the temperature of the air leaving and entering your system, as a significant difference between these two temperatures indicates that insulation is needed.

Step 2: Ensure To Wear Safety Equipment

It would be best if you had an idea that whenever you are working on a project that includes fiberglass insulation, you’ve to take extra care of your safety equipment. So, remember to wear safety glasses, gloves, and a protective mask. Also, make sure to ventilate the area well during and after you finish your insulation project.

Step 3: Shutdown The HVAC Unit

It may be harder to insulate the duct system when used. Make sure to turn off the duct system so it can be insulated conveniently. If the system works, it’ll vibrate, and vibrating ducts can lead to slipshod insulation. Ensure the system is turned off before starting.

Step 4: Measure Accurately

Using a tape measure helps you figure out the circumference of your air duct network. It also lets you decide how wide you want each insulation piece.

Afterward, you can use a knife and measuring square to cut out the part of insulation that is larger to wrap around the ductwork’s circumference. Remember that insulation won’t work properly if you make it too tight so avoid forcing a tiny piece to wrap around your air duct. The insulation should fit snugly against the ductwork without mashing or stretching.

Step 5: Seal The Insulation Using Metallic Foil Tape

After wrapping the section of tape on your ductwork in the insulation, take some areas across the gape so the insulation can be held correctly. Then, use some more pieces of tape down the whole length of insulation so the duct woke network can be appropriately sealed, and you can avoid an air leak issue.

Make sure to fill all the gaps in the insulation using metallic foil tape, including between the insulation parts. If the insulation isn’t taped together securely, you might get your desired results. Use duct mastic to a place where there is a connection between the elbow and joint.

Step 6: Repeat The Process As Required

The project will be completed once you’ve wrapped up all the ductwork gaps with insulation. You may have to fill awkward bends and joints, mainly when working on an older duct. Ensure to measure every piece of insulation for coverage entirely. Also, if you find any air leaks, use more tape to cover them up and insulate ductwork.

Step 7: Inspect Gaps

Once your air ducts are wrapped around the insulation, you must recheck your hard work. So if you’ve missed any gap by mistake, you can fill it. At this point, turn on your HVAC ductwork system to get a good idea of whether the air is escaping from it. If you find any gap in the insulation, fill it with tape.

Step 8: Test The Insulated Ductwork

Last but not least, you need to test your insulated ductwork. Turn on the air conditioning and measure the temperature of the air coming in and out of the system. If you notice a decrease in temperature or any other issue, you may need to inspect for any holes or cracks that weren’t sealed properly.

Keeping in mind these steps, you can efficiently install ductwork insulation. Soon you’ll start noticing savings on your energy bills each month.

FAQs

1. How Do You Choose The Right Ductwork Insulation?

We mentioned different types of duct insulation earlier in the article. However, the power of every kind of insulation material is measured by its R-value. The higher an insulation material’s R-value, its external temperature is more resistant. Remember that insulation with a higher R-value will be more expensive than the lower one. For instance, a list of insulation materials starts from the lowest R-values to the highest.

- Loose (blown-in) insulation

- Blanket insulation

- Spray foam insulation

- Foam board insulation

The crucial R-value for insulation depends on the country you reside in.

2. Why Does The Ductwork System Need Cleaning?

Pay attention to cleaning your ductwork network so the system can perform properly and efficiently. There are other issues, such as insurance compliance, if the system needs to be cleaned.

3. What Is The Difference Between Air Ducts And Air Vents?

The primary purpose of an air duct network is to direct the air that enters through the air vents to the primary heating or cooling of the central year unit. Moreover, the air duct helps guide the air that has been heated or cooled back out of the air vents throughout the house.

4. What Is The Best Type Of Ductwork?

Flexible ductwork is the best system to use in tight areas where you cannot insulate rigid ductwork as they are adjustable, so you can easily bend them around any fixed structure.

5. Where Are Ducts Used For?

Usually, ducts are passages that are used in ventilation, heating, and HVAC (air conditioning systems) to receive and remove air. Commonly ducts also deliver ventilation air as part of the supply air.

Conclusion

Follow the steps to properly insulate your ductwork and minimize energy loss from your heating and cooling system. A well-insulated duct system will result in major energy savings but can also help maintain a constant indoor temperature throughout the year. Enjoy the comfort of your home and the savings on your energy bills with a properly insulated duct system.

Don’t forget to check your local building codes for additional insulation regulations and insulation requirements. Professional help is recommended if you are unsure about the best way to insulate your ductwork. Insulating your ducts can be easy and rewarding, so get started today!