Comparing different insulation materials can be difficult, as each type has unique advantages and drawbacks. Rigid foam is often praised for its ability to seal air gaps and add structural support, while fiberglass insulation offers superior noise reduction and thermal performance.

This article will help you determine what’s right for your home or building by discussing the pros and cons of rigid foam vs fiberglass insulation. We’ll look at their respective strengths, weaknesses, R-values, costs, health concerns, and more so you can choose which material to use for your specific project.

Regardless of what you decide, installing quality insulation is key to a more comfortable home and lower energy bills – now that’s something everyone can get behind!

Rigid Foam Board Insulation

The material for making rigid foam is usually polyurethane, Polyisocyanurate, polystyrene, styrofoam insulation, and other polymers. You can buy it in the form of structural insulated panels and sheets for insulating it on the existing or under-construction walls.

Remember that if you’re re-insulating your home, you must remove the drywall before insulating rigid foam. The rigid foam insulation will work best if your home is a conventional, rectilinear design with concrete block walls.

If you want something specific, rigid foams can also be customized with a vapor barrier. Moreover, they are available in various sizes, shapes, thicknesses, and facings. You can make the rigid foam the way you like by cutting the panel into any size or shape.

Types of Rigid Foam Insulation

Types of rigid foam depend on the manufacturer; properties can differ slightly. The numerous manufacturer’s processes have created three types of rigid foam insulation that includes:

1. Excluded Polystyrene (XPS)

Excluded polystyrene is manufactured through a constant excursion process. The process produces a homogeneous, closed-cross-cell section highly resistant to moisture, heat transfer, and humidity.

Moreover, these foam boards are long-lasting and maintain their R-values pretty well, even during the cold season when the temperature is down; these foam boards are highly resistant to moisture so you can use them for kitchen or basement insulation.

XPS rigid boards typically have an R-value of around 5 per inch of thickness. You can quickly identify them because of their distinctive panel colors, which are green, blue, and pink.

2. Polyisocyanurate (Polyiso) Foam Board

Polyiso or Polyisocyanurate for board insulation is a close-cell or rigid structure containing two face sheets that sandwich foam cores between them.

The process of manufacturing polyiso foam board begins with a spray of liquid foam against a substrate layer to manufacture a rigid panel.

The face sheets can be manufactured using foil, paper, or other organic and inorganic materials. All these elements will form rigid insulation boards used in residential buildings specifically for flat roofing applications.

Remember that these types of rigid boards cannot be recycled or reused. The R-value of polyiso panels is around 5.8 to 6.0 per inch.

3. Expanded Polystyrene (EPS)

Expanded polystyrene is the most popular form of rigid foam insulation. The R-value of EPS is typically around 4.5 per inch of thickness.

The manufacturing process of EPS begins by expanding spherical beads in a mold. Afterward, pressure and heat are applied to fuse the beads.

EPS rigid boards generally insulate residential buildings’ roots, walls, attics, and floors. Expanded polystyrene is an exterior insulating sheathing material that can be used both above and below grade.

Moreover, it is the most cost-effective rigid foam insulation that exceeds most building and energy codes. Also, it doesn’t lose its quality, degrade or settle over time. Considering your requirements, you can buy EPS foam board panels in various densities and thicknesses.

Characteristics Of Foam Board Insulation

All types of foam board insulation have some similar characteristics or features. These characteristics are:

Good eat-resistant properties. Also, these are the exceptional insulating materials that have the highest R-values.

The R-value of rigid boards is typically around 4.0 to 6.5 per inch of thickness.

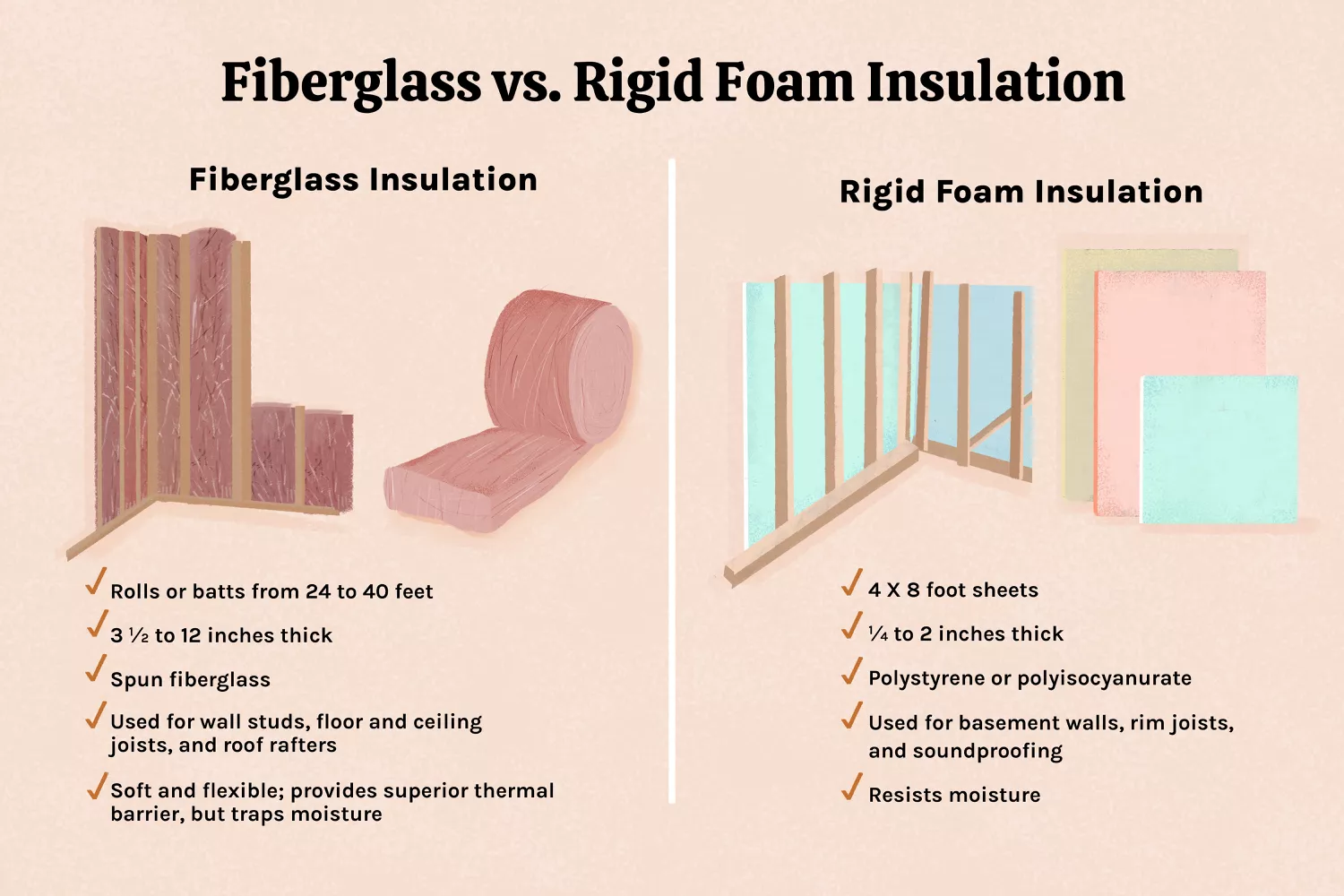

Generally, you can buy rigid boards in sheets about 4 feet by 8 feet in size. The thickness of these boards will vary between 1/4th to 2 inches.

Rigid foam insulation is famous for being long-lasting and dimensionally stable. It doesn’t contract or expand even in extreme weather conditions, moisture, or other external influences.

A rigid foam panel can be cut using a blade or serrated knife to fit in the area you want to install. It also can be used to insulate crawl spaces, rim joists, foundation walls, attic floors, or roof decks.

The foam board panels can be fixed in place using screwdrivers and silicone caulk. The insulation board installation process is straightforward and can be finished with a single DIY.

The rigid foam boards are susceptible to sun rays and can be destroyed by exposure to ultraviolet radiation. They aren’t suitable for sealing gaps and holes in building envelopes.

Fiberglass Insulation

Fiberglass Insulation comes in tightly packed rolls of extremely thin or delicate glass fibers. You’ll see fiberglass insulation, most commonly in American homes. The raw materials that use in the manufacturing of fiberglass insulation are:

- Calcined alumina

- Limestone

- Magnesite

- Borax

- Kaolin clay

- Silica sand

- Soda ash

- Feldspar

During the making of fiberglass, the mentioned ingredients are mixed and melted at a temperature of 2500°F or more. Afterward, the molten raw materials come out of the furnace and into a perforated metal container which is cylindrical and continuously rotating.

When the perforated container spins, the molten glass flows out of the tiny holes in its body. When the molten raw flows out, the glass changes its texture to thin and threadlike filaments.

Threadlike filaments are tightly stuck together, so a strong blast of cold air will help separate each molten glass filament into numerous short stands. Afterward, these stands then fall into a conveyor belt. They combine to form the fleecy fiberglass insulation batts available in home improvement stores.

The complex manufacturing process of fiberglass insulation allows it to resist heat flow. The fleecy glass fibers can efficiently trap air pockets, helping slow the movement of heat flow through the material.

Types Of Fiberglass Insulation

Generally, fiberglass insulation comes in two types. Each type has distinct features and applications and a few benefits and drawbacks. Here are its types:

1. Loose-Fill Fiberglass

Loose-fill fiberglass insulation contains tiny particles of glass fiber that can be used to finish wall cavities and attics. A mechanical blower should be used while installing loose-fill fiberglass installation.

Usually, loose-fill fiberglass insulation is more prevalent among building contractors and architects because of its few characteristics: non-combustible, heat/fire resistant, and inorganic. Inorganic properties also make the insulation material resistant to growing mold, fungus, and mildew.

The process is straightforward if you want to increase the R-value of loose-fill fiber. You only need to add several fiberglass particles blown into a given space. Moreover, it does not absorb moisture and will not rot or settle over time.

2. Fiberglass Batts

Fiberglass rolls are widely used for insulating residential and commercial spaces. Generally, these batts are around three to six inches in thickness. You can cut it into various shapes and sizes and install it following a simple DIY process.

Fiberglass batts or rolls are made by keeping layers of molten glass filaments on top of one another on a conveyor belt till the needed thickness is achieved. The R-value increases with consistency, typically around 2.9 to 3.8 per inch of thickness.

Comparison Between Rigid Foam Board And Fiberglass Insulation

Fiberglass Insulation and rigid foam boards are different from each other in their structure and properties.

1. Application

Fiberglass Insulation is one of the most common types due to its effectiveness and versatility. Fiberglass batts are usually applied in exterior walls and attics because of their excellent property of heat prevention through the wall panels and ceilings. It is most commonly used to insulate distinctive architectural elements.

Rigid foams are more resistant to moisture than fiberglass, which is why they are widely used in kitchen areas, basement walls, and other parts of homes that are prone to humidity. However, rigid boats aren’t flexible like fiberglass, so they’re not the best option to insulate on irregular surfaces such as arches.

2. Cost

Fiberglass Insulation is cost-effective compared to rigid foam boards. When you choose to insulate fiberglass, you can pay at most $0.88 to $1.64 per sq. foot of insulation, including labor costs. The exact amount of insulation will be determined by the R-value of the insulation and fiberglass type.

Rigid boards are more expensive, costing around $2 to $2.5 per square foot of insulation. It means you’ve to pay double the price for insulating the same space with rigid foam instead of fiberglass rolls. Loose-fill fiberglass insulation is expensive but not like rigid foam boards. You can still purchase within your budget.

3. R-Value

Regarding thermal resistance, rigid foam boards are undoubtedly more capable than fiberglass. As a result, wooden foam boards have a higher R-value than fiberglass.

Loose-fill fiberglass has an R-value of around 2.2 to 2.9 per inch of thickness. At the same time, fiberglass batts’ R-value is typically about 2.9 to 3.8 per inch.

In addition, rigid foam board insulation R-values range from 4.0 to 6.0. However, if you want to increase the R-value of loose-fill fiberglass, it can be increased by blowing loose fibers into a given space. But the rigid foam boards have a fixed R-value that you cannot change easily.

4. Installation Process

The rigid foam board insulation process is challenging compared to fiberglass. As the name says—rigid foam cannot be bent, but fiberglass is flexible. However, you can cut wooden foam boards easily into any size or shape. Remember that you cannot fix them around wires, vents, electrical outlets, and other obstructions.

Whereas fiberglass batts are highly flexible, you can easily fit them around wires, vents, electrical outlets, etc. But you can only insulate fiberglass batts if you’re an expert, so it’d be better to call a professional technician. Also, remember to use safety gear such as gloves, goggles, and masks while insulating fiberglass.

Conclusion

Comparing rigid foam and fiberglass insulation, both materials have their own merits. You should choose the material that best suits your needs and project. Rigid foam insulation is superior in insulating value, moisture resistance, and durability, but it can be more expensive than fiberglass insulation. On the other hand, fiberglass insulation is easier to install and offers a lower upfront cost than rigid foam.

Ultimately, it comes down to your individual needs and budget to decide which material is better for your project. No matter what you choose, ensure the job is done correctly by a professional installer to reap the full benefits of either insulation type.