For homeowners who want to ensure that their basement stays mold- and moisture-free, a crawl space vapor barrier is essential to their home maintenance. The barriers are designed to prevent water from entering the crawl space, which helps reduce condensation and keep the indoor environment clean and healthy.

Several types of vapor barriers are available on the market today, so it’s important to familiarize yourself with each type and consider which one best suits your needs. Let’s discuss this in detail.

Why Choose a Crawlspace Vapor Barrier?

Sealing off your crawl space means you’ve protected rodents, bugs, or other pests looking for ways to get into your home. Moistures are the culprit behind inviting undesirable guests to your residence.

Moreover, moisture can also destroy the subfloor of your home and the foundation. Depending on the type of destruction, the expenses of cleaning and repairing a crawl space can be high, which is why you need the preventive measure of installing a vapor barrier.

Sealing an open crawl space with a vapor barrier can protect against moisture accumulation in your home’s floor and living areas. It also helps save your home from wood rot, mold spores, and energy losses.

Vapor Barrier Material Options

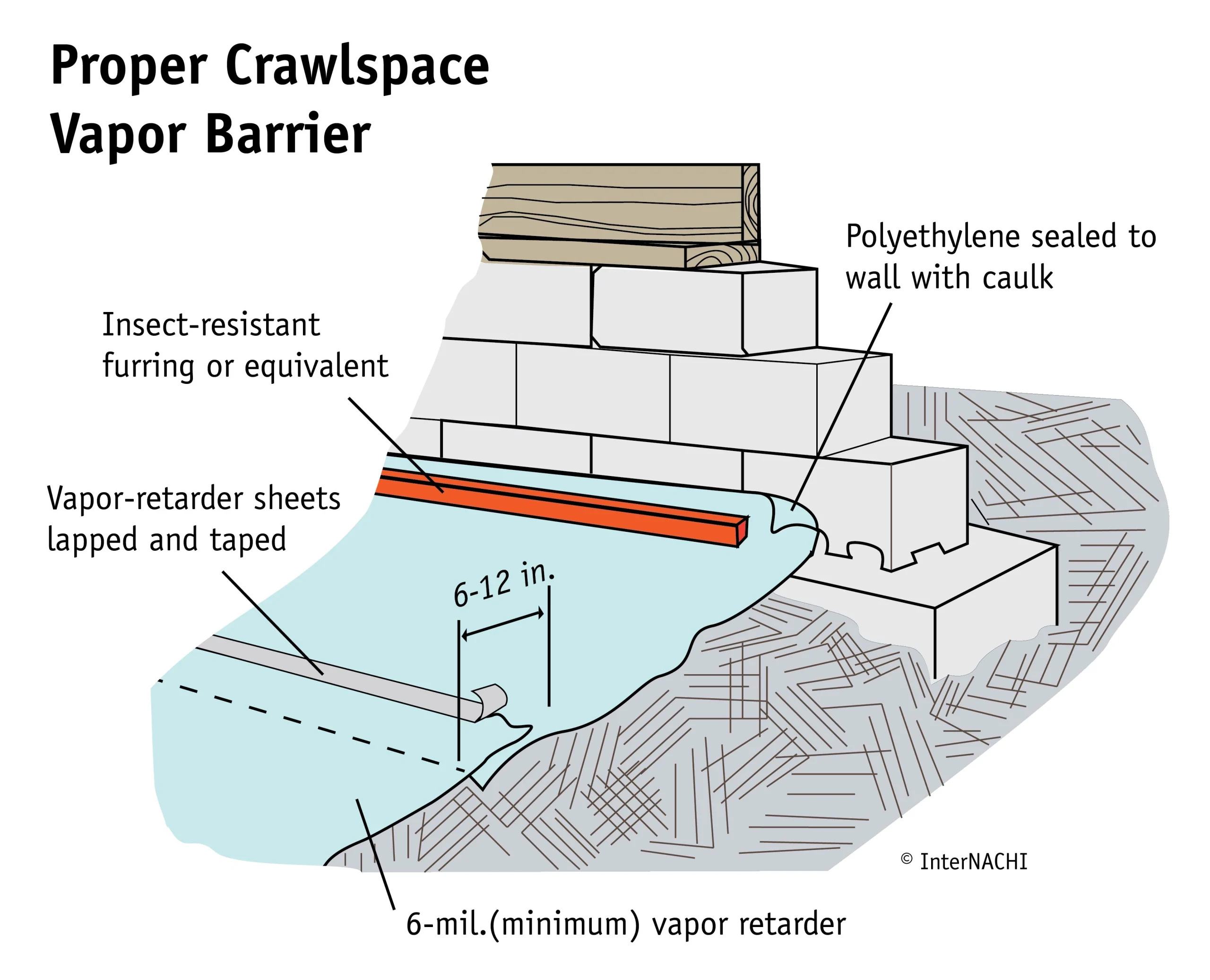

The most important material type of crawl space vapor barrier is reinforced polyethylene plastic sheeting, also known as poly. It comes in a variety of thicknesses and strengths. The commonly used vapor barrier is six mils and offers savings for the short term to homeowners. However, you’ll see those savings vanishing after a short span. Someone walking or crawling on the barrier will cause micro holes.

With those micro holes, it’ll no longer perform the way it should. Due to this, the experts suggest 10 mil and higher than that for long-term vapor protection, depending on the soil conditions.

Another concern is that the polys in local hardware stores are usually thinner. Those are not only thin but also non-reinforced and possibly made up of recycled or regrind poly.

Regrind poly is full of impurities that include dirt or moisture. If you want to use regrind or thinner plastic, it’ll be okay for short-term use. However, it would help if you used reinforced virgin poly for longer periods, such as crawlspace vapor barriers. Properly installed pure poly can last up to 20 years or more in a crawl space.

The Right Vapor Barrier Thickness

You should know two types of measurement while choosing your poly for your crawl space barrier. “Mil” and “perm” are the two terms you should be familiar with. “Mil” is the measurement of the poly’s thickness, and the “perms” term represents permeability to moisture.

1. Mils

Polyethylene sheeting is measured in “Mils.” A mil is equal to 0.001 inches of thickness. Codes for residential applications often cite a six-mil (0.0006-inch thick) minimum reinforced poly vapor barrier. However, the expert suggests 10 mils or higher than that, approximately up to 20 mils.

2. Perms

The perm rating shows how readily water vapors will pass through a material. The lower perm rating means less permeable material. As it falls into the vapor barrier category, a material must have a perm rating of 0.1 or below. Poly sheeting that contains six mils (0.06 perms) and thicker meets this bare minimum.

Choosing the Right Crawl Space Vapor Barriers

The thickness of the poly you choose will mainly depend on two factors:

- Utilization of crawlspace (storage, maintenance, etc.).

- Soil or material on the floor of the creak space.

You’ll need to figure out how much poly sheeting you’ll require to cover your crawlspace. Keep in mind to get sufficient material to overlap 6-12 inches at the seams. A 6-foot-wide roll will cover most of the foundation walls effectively. However, it would help if you had a wider roll for the floor.

There are four main parts needed to make the crawl space barrier successful.

- Moisture protection

- Durability

- Longevity

- Value

The type of specialty products, including crawl space vapor barriers, must have the capability to function in challenging situations. That does not mean you must have different vapor barriers for different conditions. However, the crawl space barrier that you are installing must be capable of handling different situations.

Encapsulation Vapor Barrier Thickness

Painter’s plastic is 6 mil or less and usually is 0.5 mil. It is used to create boundaries between rooms. Most water companies use 0.5 mils to 6-mil plastic to make containment areas.

Crawl space vapor barriers are mostly at 10 mils at the lowest, and some get over 20 miles in a few areas. Now the question may arise in your mind why most crawl space companies use thicker mil plastic compared to the other industries.

Vapor Barrier Perm Rating

The perm rating explains the mass rate of water vapors flowing through one square foot of material.

So the class 1, 6 mil polyethylene sheeting at the hardware store has a perm rating of about 6.0. This perm rating is the minimum thickness rating accepted as a ground cover in a building code at the crawl space.

Class 1 Encapsulation Vapor Barrier

Class 1 vapor barrier, also known as a vapor retarder. It is the only type that is accepted by the building code that is used in building spaces.

The class is defined using the desiccant method of ASTM E 96:

- Class 01 Vapor Barrier – 0.1 perm or less.

- Class 02 Vapor Barrier – 0.1 perms to 1.0.

- Class 03 Vapor Barrier – 1.0 perm to 10.

The desiccant testing method is completed at 25% relative humidity level to get the above-mentioned perm.

Class 2 Vapor retarders are considered semi-impermeable. Examples of Class 2 vapor barriers are unfaced expanded polystyrene and kraft-faced fiberglass batt insulation.

Class 3 examples can be, say, latex paints over drywall. Avoid using paint in crawl spaces because it is also considered semi-permeable.

Types of Crawl Space Vapor Barriers

There are different types of crawl space vapor barriers; let’s discuss them in detail.

1. String Reinforced Polyethylene Vapor Barriers

The first and most popular type of vapor barrier is reinforced polyethylene plastic. Reinforced plastic sheeting is manufactured by laminating layers of high-strength polythene with a heavy-duty scrim reinforcement between them. The manufacturing layers make a powerful film highly resistant to tearing and more durable than construction-grade poly.

The reinforced polyethylene vapor has numerous benefits, including increased strength and durability, improved tear resistance, UV protection, and resistance to punctures and various other environmental dangers. Moreover, it also offers extreme tear and puncture resistance. Such resistance makes it a great option for construction enclosures, temporary containment, and underlayment. In addition, reinforced vapor sheeting is affordable compared to other materials, making it a pocket-friendly alternative.

2. Non-Reinforced Polyethylene Vapor Barriers:

As the name says, it doesn’t have any reinforcements. This vapor barrier is manufactured from polythene too. As it is made without any reinforcements, it is less durable in a crawl space environment.

The excellent quality vapor barrier keeps the good quality ground moisture requirements barrier while keeping in check the manufacturing expenditures. This vapor barrier is a white, single-layer, pure virgin polythene film used for crawl space encapsulation.

The excellent quality non-reinforced was designed to offer the same moist protection you get from the reinforced vapor barriers without costing reinforcement. Many homes will not have high traffic after having encapsulated crawl spaces, so reinforcement might not be needed.

3. Coated Woven Crawl Space Liners

It can be considered a vapor barrier, but frequently it is a vapor retarder. The reason is that the center is woven with polyethylene ribbons like a trap and then coated with a thin, 1 mil layer of colored or clear polythene on both sides. The woven ribbons make such products highly stronger, but one scrape by a sharp rock and the outer side of the layer film is compromised.

4. Hybrid Woven Crawl Space Liners

The hybrid woven crawl space liners use the ribbon reinforcement of the coated woven and the film layers of a string reinforcement that makes a product that outperforms both. The strong polyethylene ribbons improve the tear and puncture strength of the barrier to 3× stronger than string reinforced, and the film layers improve the crawlspace moisture protection over the coated woven.

5. Plasticized Aluminum Liners

The plasticized aluminum liner in the entire crawl space floor barriers is new to this scenario. It is manufactured with a thin coated woven liner (3 Mil including the outer layers on one side), an open cell center, and a plastic film with some aluminum mixed in 1.5 Mil on the second side.

This product boasts a 0 perm rating because of the “aluminum” layer, but the actual scenario is different. For instance, if the product were 0 perms, the installation wouldn’t be possible. The 0 perms would be compromised with the seams, support, and workmanship. Even if we allowed this product only claim to fame. The thin layers would prevent this product from performing due to its minimum durability.

Conclusion

Compare the different types of crawl space vapor barriers to decide which is right for you. Consider the cost, performance, durability, and installation requirements when making your decision. A properly installed vapor barrier slows the evaporation. It helps keep your home comfortable and energy efficient while reducing the risk of water damage and mold growth in your crawl space. Take the time to consider all options before deciding on a vapor barrier for your crawl space to ensure the best possible outcome. No matter what type of vapor barrier you choose, investing in a reliable and quality product can save you time, money, and frustration.