Thermal insulation is essential for various energy, industrial, and medical industries to ensure optimal performance. By introducing a barrier between two objects or fluids, heat transfer can be significantly reduced – making insulation a critical component of many systems. Different technologies are used to solve the thermal challenges faced by these applications.

The blog will provide an in-depth guide to thermal insulation and its various uses. From common thermal insulation materials to their applications in industrial and other settings, we will provide a comprehensive understanding. Read on to learn more about this versatile insulation!

What Is Thermal Insulation?

Thermal insulation inhibits thermal energy transfer between objects in thermal contact by conduction, convection, or radiation. Insulation materials with low thermal conductivity prevent heat flow in buildings, manufacturing processes, refrigeration parts, mechanical systems, and automotive internal combustion engines.

Thermal insulation is not limited to building insulation but can be found in everyday areas of our lives, such as insulated bottles, clothing, and protective gear for firefighters.

Conduction transfers heat within or between solid objects, convection transfers heat through fluid movement, and radiation transfers heat outward from light or gas. Insulators minimize or prevent the transfer of heat energy by any of those means. Thermal conductivity, density, and heat capacity are important properties of insulating materials depending on their use.

How Does It Work?

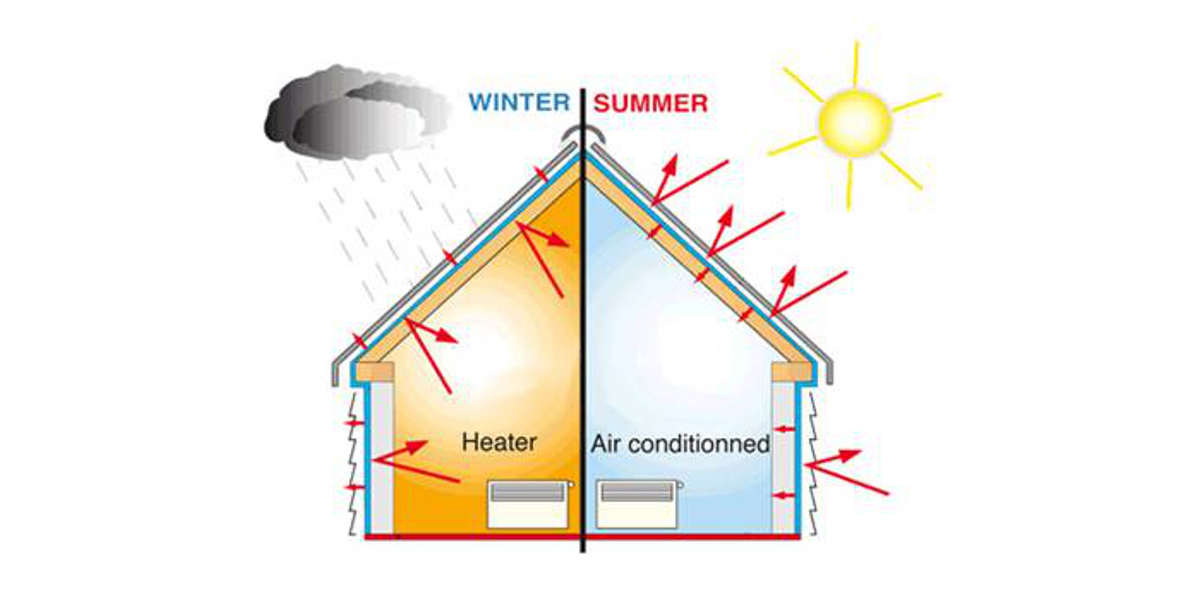

Thermal insulation is a barrier that reduces heat transfer between a hot and a cold object. This can be achieved by reflecting thermal radiation or reducing thermal conduction and convection.

Radiant barriers and reflective insulation are designed to minimize radiant heat gain and effectively reduce heat transfer.

The R-value of thermal insulation is a measure of its insulating ability. A higher R-value indicates better insulation performance, and increasing the thickness of the insulation directly increases the R-value. The recommended insulation thickness may vary depending on where you live, and R-values can range from R-1.5 to R-7.

The insulation helps maintain the desired environment by preventing heat loss from a system. It offers various benefits, such as increased energy efficiency and reduced energy costs.

For instance, properly insulating homes can significantly lower homeowners’ annual heating and cooling expenses. Similarly, in a process plant, insulated pipes can keep fluid streams from transferring heat to surrounding environments, enabling the delivery of fluids at the desired outlet temperature.

Apart from the primary use cases, effective thermal insulation is vital in ensuring efficient and safe operations in several industries, including power plants, manufacturing, food and beverage, petrochemical, and oil and gas.

Most Common Thermal Insulation Materials

Some of the most common materials used for thermal insulation include fiberglass, cellulose, foam, rock wool, and various plastic foams. Each material has advantages and disadvantages, so it is important to consider your project carefully before deciding which one to use.

1. Fiberglass

Fiberglass insulation is commonly used in modern times due to its effectiveness in minimizing heat transfer. The insulation material is made by weaving fine strands of glass together.

- Fiberglass is non-flammable, making it an excellent insulation material.

- However, handling fiberglass can be dangerous without proper safety equipment.

- The material is made of finely woven silicon, which can cause damage to the eyes, lungs, and skin.

- Proper safety equipment such as eye protection, masks, and gloves should be used when installing insulation.

- The R-values of fiberglass insulation range from R-2.9 to R-3.8 per inch, making it a cost-effective insulation option.

2. Cellulose

Cellulose insulation is eco-friendly and made from recycled cardboard, paper, and similar materials. It is loose and has an R-value ranging from R-3.1 to R-3.7.

- Recent studies have shown cellulose may be an excellent product for minimizing fire damage, as it contains little oxygen within its compact material.

- Cellulose is both eco-friendly and fire-resistant, making it a desirable insulation option.

- However, some people may be allergic to newspaper dust in cellulose insulation.

- Finding individuals skilled in using this type of insulation may be more difficult than with fiberglass.

- Despite these downsides, cellulose insulation is a cheap and effective insulating method.

3. Mineral Wool

Mineral wool is a type of insulation that refers to several different materials. These materials include glass wool, rock wool, and slag wool. Slag wool is the most commonly used mineral wool in the United States.

- Mineral wool is available in batts or as a loose material.

- It is not inherently fire-resistant, but it is not combustible.

- When used in combination with other fire-resistant insulation, mineral wool can be effective for insulating large areas.

- Mineral wool has an R-value ranging from R-2.8 to R-3.5.

4. Polystyrene

Polystyrene is a waterproof thermoplastic foam insulation material for sound and temperature. It is available in two types: expanded (EPS) and extruded (XEPS), commonly known as Styrofoam. XEPS, which is more expensive, has a higher R-value of R-5.5 than EPS, which has an R-value of R-4. Polystyrene insulation stands out for its smooth surface, unlike other insulation types.

The foam is usually formed or cut into blocks, making it ideal for wall insulation. However, it is highly flammable and requires the application of a fireproofing agent called Hexabromocyclododecane (HBCD). The use of HBCD has recently faced criticism due to its potential health and environmental hazards.

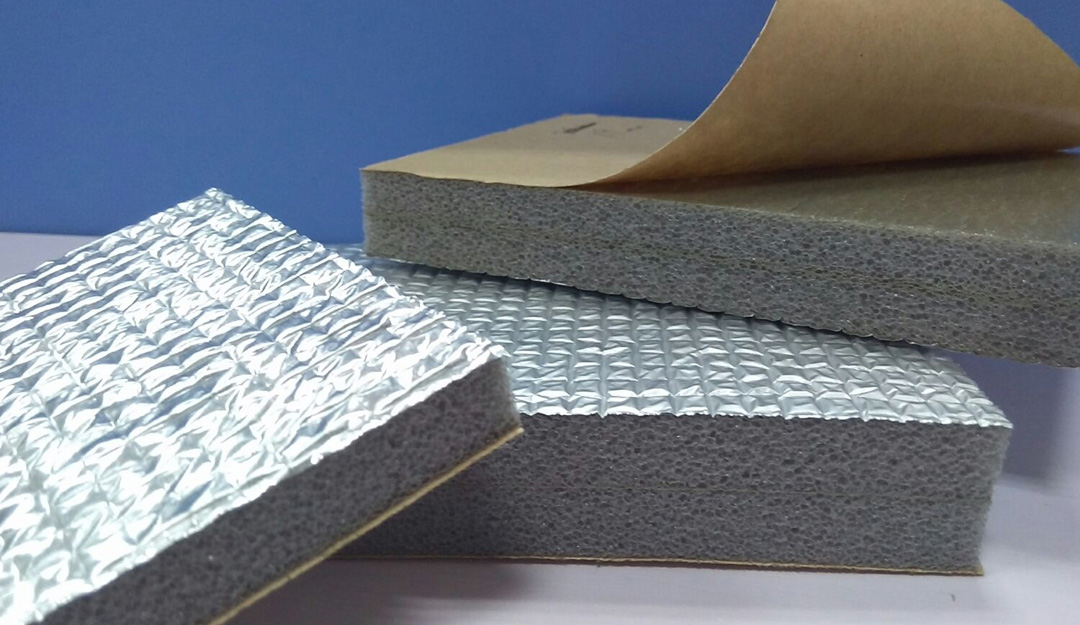

5. Polyurethane Foam

Although not very common, polyurethane foams are a great insulation material due to their properties. Modern polyurethane foams use eco-friendly blowing agents that do not contribute to ozone depletion. They are lightweight, weighing around 2 pounds per cubic foot (2 lb/ft^3), and have a high R-value of about R-6.3 per inch of thickness.

In addition, low-density polyurethane foams are available that can be easily sprayed into areas without insulation. These foams have an R-value of approximately R-3.6 per inch of thickness. Polyurethane insulation also offers fire resistance, making it a safer option for homes and buildings.

Which One Should You Choose?

Depending on the situation, the most suitable type of insulation can vary drastically. For instance, when constructing a new building, options may differ from that used for renovating an older home. That said, closed-cell foam is one of the best options available regarding R-value – about 6.2 per inch – although it comes at a cost. It’s important to weigh your options carefully and do extensive research before deciding which type of insulation is the best for you.

How To Install Thermal Insulation

Having the right materials is essential to install thermal insulation properly. You’ll need some tools, like safety glasses, a face mask, gloves, and measuring tape. Depending on the insulation you’re installing, you may also need other goggles and protective gear.

Once everything is gathered and ready to go, it’s time to begin installing thermal insulation. The steps include:

1. Building Codes

You’ll need to research and understand the applicable building codes for your area. Be sure to check for any vapor barrier requirements, and determine the required R-value of insulation in your area.

2. Creating Access Points

Create access points so that you can reach all areas with insulation material. This may include sealing around plumbing, ductwork, wiring, crawlspace, windows, and basements. Caulking or foam insulation material should be used to prevent air leakage.

3. Measurements

Take measurements for the space you’re insulating, such as between joists in attics, studs in unfinished walls, and the thickness of framed walls. Calculators available online can help you with your estimates.

4. Installing Insulation

Place the insulation material and ensure it fits properly in all areas. Make sure to cut any pieces too long or wide to fit properly, and fill any gaps with additional insulation material if needed.

5. Double-Checking Your Work

Finally, double-check your work. Ensure all insulation material is placed correctly and no gaps or air pockets. Check for potential hazard areas where insulation can come into contact with wiring or other combustible materials.

Double-Wall Vs. Vacuum Insulation

Both double-wall insulation and vacuum insulation are effective forms of thermal barriers. Double-wall insulation traps a gas like argon between two solid layers to reduce heat transfer. Vacuum insulation is similar but evacuates the space between walls for more powerful temperature control.

Advanced vacuum insulation is sought after for systems requiring the highest energy efficiency and for those in which more traditional insulation materials may not be suitable. Both forms of insulation are effective for slowing down heat transfer and creating a better-regulated environment.

A key factor to consider when selecting an appropriate form of thermal insulation is the insulation’s effectiveness over time. Double-wall insulation can provide reliable protection from heat transfer, but vacuum insulation may offer more long-term protection.

When choosing an insulation system for your space, it is important to assess the specific conditions and needs of the application to determine which type of insulation is best suited for you.

How To Insulate Against Radiation

Reflective materials with low emissivity are commonly used for insulation against radiation, particularly in ultra-high temperatures and critical applications. These materials, such as aluminum foil, effectively reflect thermal radiation, allowing objects to retain their thermal energy for longer periods.

One example of using reflective materials for insulation against radiation is wrapping hot food in aluminum foil. The foil reflects the infrared radiation emitted by the food, helping it to retain its heat.

Another insulation technique that utilizes radiation reflection is super vacuum insulation (VSI), which combines a vacuum-insulated system with multi-layer insulation (MLI). MLI is a highly advanced thermal insulation material that can reflect significant radiation heat transfer.

Conclusion

The right thermal insulation material can manage many applications successfully and efficiently. Advanced insulation solutions such as vacuum insulation can offer superior performance and energy savings to thermally demanding applications. Consider your needs carefully when selecting an appropriate temperature insulation material. It might just make all the difference between success and failure.

Proper insulation is essential to modern buildings, and understanding these materials is key to creating a comfortable, energy-efficient environment. So go forth confidently—armed with this ultimate guide to thermal insulation, you’re ready to make your home or business more efficient than ever before. Let the savings begin!